Advanced Ship Automation Using AMC 300 and AMC 600 Controllers

Modern ships are no longer operated only by human hands and mechanical switches. They are driven by intelligent automation systems that constantly monitor, control, and protect hundreds of onboard processes at the same time. Every key system on a ship, including power, fuel, engines, and safety, depends on the automation controller.

A ship operates in one of the most demanding environments on earth. High vibration, extreme temperatures, salt air, humidity, and electrical noise are part of daily life at sea. This is why marine automation controllers must be far more rugged, reliable, and secure than those used on land.

DEIF AMC 300 and AMC 600 controllers are built exactly for this kind of environment. They are designed to bring advanced control, real-time monitoring, and digital connectivity to ships of all sizes. With these controllers, ship operators gain higher efficiency, safer operations, and better visibility into every critical system on board.

Understanding Ship Automation Systems

Ship automation is the backbone of modern vessels. It connects engines, generators, pumps, alarms, navigation systems, and safety equipment into one intelligent network. The controller sits at the center of this system. It receives data from sensors, makes decisions based on programmed logic, and sends commands to equipment.

A strong automation controller helps ship operators to:

- Reduce manual workload

- Improve fuel and energy efficiency

- Detect faults early

- Prevent system failures

- Enable remote monitoring

- Improve safety for crew and cargo

The AMC series from DEIF is widely used in marine and offshore industries because it is built to handle both control and communication in harsh operating conditions.

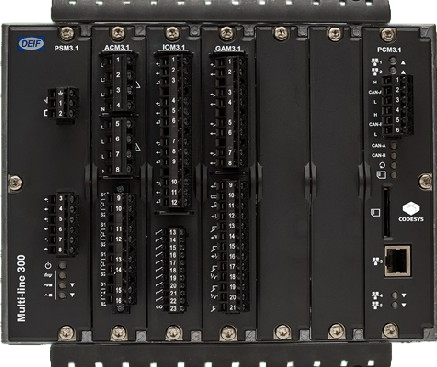

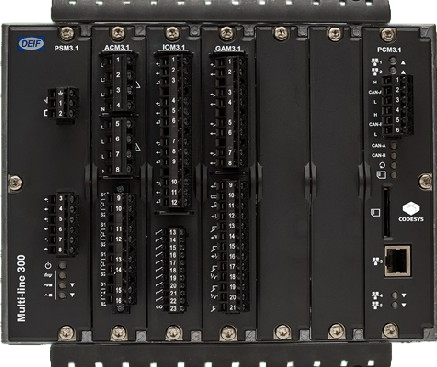

AMC 300

The AMC 300 is a powerful programmable automation controller designed for marine, offshore, and near-shore applications. It is built to operate in extremely cold and hot conditions and continue working even under shock, vibration, and electrical disturbances.

This controller is ideal for shipboard auxiliary systems, power management, safety monitoring, and machinery control.

Why AMC 300 is Unique

One of the most impressive features of AMC 300 is its ability to start and operate at minus 40 degrees Celsius. This makes it perfect for vessels operating in cold climates or offshore platforms exposed to extreme weather.

It uses a base-mounted rack and a metal cabinet that protects it from vibration, bumps, and shocks during both operation and transportation. Its internal backplane design ensures that communication between I O modules remains stable even when the ship is moving in rough seas.

The system is also protected against lightning, power surges, and electrostatic discharge. This means fewer failures and less downtime.

Smart and Secure Software Platform

AMC 300 runs on a Linux-based operating system maintained by DEIF. This gives it long-term stability and strong cybersecurity. It supports modern tools such as:

- Web-based configuration

- Secure user access with certificates

- Modbus TCP

- OPC UA

- CODESYS programming based on IEC 61131 3

The controller has two operating system images. If one fails, the system automatically switches to the backup. This ensures that the ship never loses control of critical systems due to software problems.

Where AMC 300 is Used on Ships

AMC 300 is commonly used in:

- Generator and power management systems

- Auxiliary engine control

- Pump and ballast systems

- Fuel treatment systems

- Alarm and monitoring systems

- HVAC control

- Safety systems

Its strong design makes it suitable for both new ships and retrofit projects.

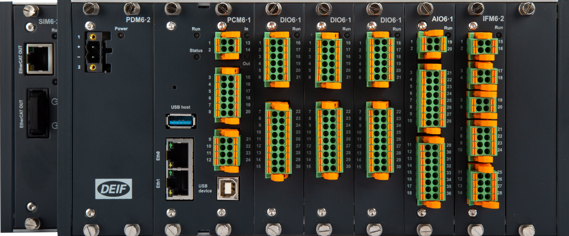

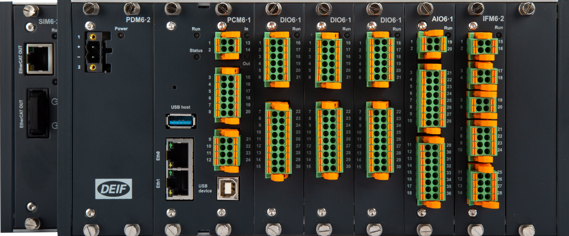

AMC 600

AMC 600 is the next-generation programmable automation controller from DEIF. It is built to offer even more flexibility, speed, and connectivity. It uses EtherCAT based I O, which allows very fast and reliable data transfer between the controller and all connected modules.

This controller is ideal for ships that require advanced automation, distributed control systems, and digital integration.

Modular and Flexible Design

The AMC 600 is based on a modular rack system. You can choose from six rack sizes and install between 4 and 14 module slots. These modules can include:

- Power supplies

- CPU modules

- Digital and analog I O

- Communication interfaces

- Condition monitoring

- Network gateways

This design makes it easy to build a system that fits exactly what the ship needs. It also allows future expansion without replacing the entire controller.

Racks can be connected in a daisy chain or star layout, allowing distributed I O across different parts of the ship. This reduces cabling and improves system reliability.

High Speed Communication

By default, AMC 600 uses EtherCAT. This allows it to handle hundreds of I O points with update cycles as fast as one millisecond. Both local and remote I O are updated at the same speed, which is essential for precise control of engines, generators, and safety systems.

In addition, AMC 600 supports:

- PROFINET

- Modbus TCP and RTU

- OPC UA

- CAN and CANopen

- J1939

- HTTPS and WSS for cloud connectivity

This makes it easy to integrate AMC 600 into existing ship systems or connect it to remote monitoring platforms.

Compact but Powerful

AMC 600 is very compact, with a rack height of only 122 mm. This makes it ideal for crowded control cabinets on ships. Its high density I O modules also save valuable space while still offering a large number of channels.

Reliable and Secure Software

AMC 300, AMC 600 runs on a Linux operating system maintained by DEIF. It supports:

- Web-based configuration

- Secure user management

- CODESYS V3.5 programming

- Web-based visualization

- Controller redundancy

It also uses a dual OS image system, so if one software image fails during an update, the system automatically switches to the backup. This keeps the ship operational at all times.

Built for Marine Conditions

AMC 600 is designed to operate from minus 40 to plus 70 degrees Celsius. It works in high humidity and resists shocks, vibrations, and electrical noise. Its conformal-coated electronics protect against moisture and salt air.

This makes it suitable for ships operating in any region, from arctic waters to tropical ports.

How AMC 300 and AMC 600 Support Advanced Ship Automation

Together, AMC 300 and AMC 600 form a complete automation solution for modern vessels. They allow ships to move from basic control to smart, connected, and efficient operations.

They support:

- Real-time monitoring of engines, generators, and auxiliaries

- Automatic load sharing and power management

- Alarm handling and safety shutdowns

- Predictive maintenance through condition monitoring

- Remote access and diagnostics

- Integration with bridge and vessel management systems

By using these controllers, ship operators can reduce fuel consumption, prevent breakdowns, and improve crew safety.

Why KDU World is Your Right Partner

Choosing the right automation hardware is only one part of the journey. You also need a trusted partner who understands marine systems and can provide the right equipment, configuration, and support.

KDU World is an authorized distributor of DEIF marine controllers, including AMC 300 and AMC 600. With strong expertise in marine automation and a presence across the UAE, KSA, Oman, Nigeria, and other regions, KDU World supports ship owners, shipyards, and offshore operators with reliable equipment and professional service.